E-CHECK Software for Tolerance Control Systems

E-CHECK Software for Tolerance Control Systems

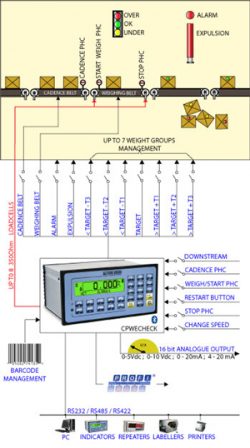

E-CHECK is a counting and verification software for managing the data received from a weighing system mounted on a conveyor belt.

It allows counting and storing transported packages/min.

You can opt for static or dynamic weighing and preset tolerance control.

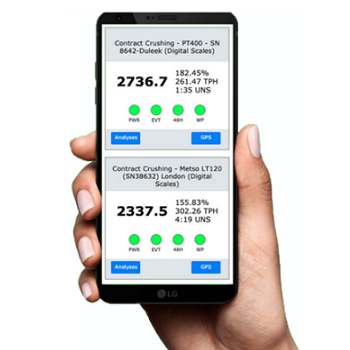

Possibility to connect to the Internet on your phone, tablet and computer, for viewing data remotely.

Software: E-CHECK, Dini Argeo, Italy

Weighing functions:

- Weighing modes:

- Static or dynamic weighing, with the management of the packet detection photocell

- Dynamic weighing with two START / STOP photocells

- Static or dynamic weighing without photocell

- Tolerance check:

- by target / default value, with the setting of 3 tolerance thresholds, for the physical division of the packages into 7 different groups

- by configurable minimum / maximum weight thresholds

- Calculation and printing of statistics and standard deviation of performed weighings

- Automatic ZERO function, static or dynamic, of the conveyor belt (up to 2% of flow) after a configurable number of weighings

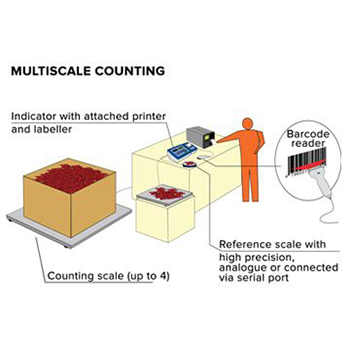

- Advanced barcode management, with the possibility of storing, processing and printing 5 different codes

- Automatic printing / deleting of the subtotal after a configurable number of weighings

- Print each performed weighing and automatically store in Alibi memory

- Configurable labels compatible with any ASCII printer manageable via the serial port

Databases:

- Database of 1000 items with alphanumeric description, target / default value and configurable tolerance thresholds

- Setting the density coefficient, for each item, for weighing in ml

- Preset tare and delay of expeller activation for each item

- Conveyor belt speed management by analog output, with configurable values for items

- Configuring the item in manual or software mode on the PC (with DiniTools)

- Select items by reading the barcode

Communication functions:

- Cycle activation, RESTART / RESET cycle and START / STOP weighing via external inputs

- Cadence band photocell management to optimize the number of packets per minute weighed by the instrument

- Manage automatic ejection or stop belts for manual ejection or weight correction

- Configure the alarm activation time and tolerance indication. Possibility to connect to the control light

- Activation of the second speed line via an external input, with automatic recalculation of the weighing time (only for weighing with two photocells)

- Analog output (optional) proportional to the weight or speed control of the conveyor belt, with configurable values for each item

- Serial communication protocol for article configuration and cycle management

- Profibus external interface (optional), for formula configuration and cycle management

- Bluetooth connection (optional), for quick wireless setup of activities and formulas, via PC or PDA

PROFIBUS main functions:

- Complete configuration of the item, automation time periods and instrument configuration parameters

- Reading the condition of the conveyor belt and the inputs, the net weight, the last weighing performed and the number of weighings

E-CHECKTOOL. Indicator configuration:

- PC software for weighing cycle optimization. Allows monitoring of the status of instrument inputs and outputs, transmission of serial commands for automation management, rapid modification of instrument parameters, visualization and graphical processing of scales for best results

We offer free telephone support* for our customers, throughout the warranty period, during working hours, and off-schedule on an appointment basis.

*weighing installation instructions, weighing calibration instructions, use and optimization of standard functions, diagnosis and solution of weighing errors, etc.

To obtain the price list, fill in the attached “OFFER REQUEST” form.

Prices may differ depending on the commercial conditions of the manufacturer.

For additional information please contact us by filling in the attached “OFFER REQUEST” form or call us at +40785207776.

You can also find additional information in the document at the bottom of the page.